Imagine spending days turning your field by hand or with multiple conventional implements versus finishing the job in a few hours with one pass of a rotavator machine. For many Indian farmers, that shift is no longer hypothetical: tractor rotavator combos are transforming land preparation. But while this tool promises speed and convenience, it also brings caveats every user must understand. In this blog, we’ll walk you through what rotavators offer, where they fall short, and how Mahindra’s offerings may help you navigate those tradeoffs.

What Is a Rotavator?

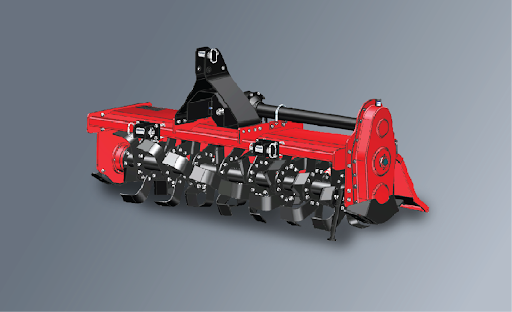

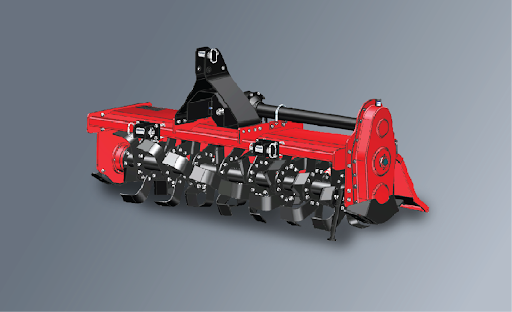

In simple terms, a rotavator machine (aka rotary tiller) is a tillage implement that mounts on a tractor and uses rotating blades to break, churn, and level soil. The blades mounted on a rotor spin and dig into the earth, mixing topsoil and crop residues in the process. When attached to a suitable tractor (hence “tractor rotavator”), it becomes a powerful tool for secondary tillage, seedbed preparation, weed control, and soil aeration.

Because the machine both cuts and mixes, it’s more than just a plough; it’s a hybrid implement designed to do multiple soil-preparation tasks in one pass.

Key Advantages of Rotavators in Modern Farming

- Time & Labour Savings

What would otherwise require multiple passes with different implements (plough → disc harrow → cultivator) can often be done in a single pass. This dramatically reduces labour costs and speeds up the pre-sowing phase. - Improved Soil Aeration & Seedbed Prep

The action of rotating blades loosens soil effectively, improving aeration and drainage. You get a fine tilth ideal for seed germination — especially helpful in small-seed crops. - Residue Incorporation / Weed Suppression

Rotavators help incorporate crop residues back into the soil and uproot weeds, helping clean the field and return organic matter to the soil. - Fuel Efficiency & Cost Savings

Because of fewer passes, lower overlaps, and optimized designs, the fuel consumed per hectare can drop. Many newer designs aim for lower power draw. - Versatility Across Crops & Soils

A well-chosen tractor rotavator can work across multiple crop cycles — vegetables, cereals, pulses reducing the need for crop-specific equipment.

In fact, Mahindra’s own research suggests their rotavators help “optimize the time and labour required for land preparation” while improving seedbed quality and residue management.

A related data point: in many mechanisation studies, farmers report saving 25–40% on labour costs when switching to a good rotary tilling setup (this figure may vary by region and conditions).

Limitations & Challenges of Rotavators

- Unsuitable for Rocky / Hard Subsoil

If your land has many stones, rocks, or very compacted soil, rotating blades may suffer damage or fail to penetrate properly. In such cases traditional ploughing may be safer. - Maintenance & Wear Costs

Blades, rotor assemblies, gearboxes, and seals wear out. Frequent replacement or sharpening of blades is essential. A cheap or poorly maintained agriculture rotavator machine may incur high running costs. - Power / Energy Requirements

Matching the horsepower of the tractor to the rotavator is critical. If the tractor is underpowered, the machine will stall or perform poorly. Overpowering is wasteful. - Risk of Over-tillage or Soil Damage

Excessive use or overly aggressive settings can harm soil structure — breaking aggregates too finely or eroding organic matter. - Operator Skill Dependence

Effective use requires proper speed, depth control, and blade angle. Poor operation can lead to uneven tilth, ridging, or damage.

How to Choose a Good Rotavator?

- Match Tractor HP & Implement Width: For example, Mahindra’s rotavator range typically supports tractors of 30–70 HP, depending on model.

- Check Rotor & Blade Design: Helix spiral blades, anti-clogging features, multi-speed gearboxes help in varied soils.

- Sealing & Gearbox Quality: A Duo-Cone sealing system (as used in Mahindra’s medium duty UM rotavator) ensures longer seal life and protection.

- Service & Spare Parts Network: It’s no use having a great implement if you can’t replace blades or get repairs quickly. This is where a brand like Mahindra, with wide dealership reach, has advantage.

- Warranty & Support: Mahindra offers warranty and support across its farm machinery range.

Mahindra’s Rotavator / Tractor Rotavator Solutions

Since Mahindra Farm Machinery lists rotavator prominently in its “Land Preparation” offerings, it’s clear this is a core area.

Some key Mahindra rotavator product lines:

- Medium Duty UM Rotavator — A lightweight yet robust design for medium soils, suitable for both dry and wet conditions.

- Standard Duty UL Rotavator, Heavy Duty UH Rotavator — to cover lighter and tougher soil conditions.

- Mahavator series — These are wider, faster machines for more demanding workloads. For example, the Mahavator is offered in widths from 1.6 m to 2.5 m (45–70 HP tractors) with multi-speed gearing.

- On the specification side, features like helix spiral rotor blades, anti-clogging membranes, side gear drives, etc., are integrated especially in their medium-duty series.

- Pricing and real-world models: Mahindra’s 5-feet rotavator models, such as Gyrovator ZLX+ and Tez-e ZLX+, are seen in the market in the range of ~₹ 88,000 to ₹ 1,50,000, depending on model and HP range.

- For larger sizes, an 8-foot Mahindra rotavator (e.g. Mahavator 2.3 m or Gyrovator SLX-230) is priced around ₹ 1.33 lakh and meant for 60–65 HP tractors.

- Beyond product specs, Mahindra’s strength lies in its service, spare parts network, dealer reach, and the backing of a major farm machinery brand. In statements from Mahindra FES leadership, they emphasise reducing labour/time and offering 2-year warranties across their rotavator range.

In effect, when you compare a generic agriculture rotavator machine to a Mahindra tractor rotavator, the latter comes with better integration, trusted backup, an aligned design with Mahindra tractors, and better support infrastructure.

Practical Tips for Effective Use

- Set the right depth & speed — too deep or too slow will strain the machine; too shallow may not break clods properly.

- Blade angle & pitch — experiment for your soil type (especially with spiral/helix blade designs).

- Operate in the correct moisture window — avoid extremely wet or too dry soils.

- Frequent maintenance — check blades, retorque bolts, lubrication, gearbox oil levels.

- Avoid overlapping passes heavily — that wastes fuel and may compact edges.

- Rotate usage — occasionally use other implements to avoid over-consolidating the structure with repeated rotary action.

Future Trends & Innovations

- Smart & sensor-based rotavators: Imagine real-time depth adjustment, vibration sensing, or adaptive speed control.

- Variable width / modular designs: So small farmers can scale.

- Electric/hybrid power assist: Especially in smaller farm settings.

- Integration with precision farming: Data-driven control of tillage depth based on soil maps.

These innovations may influence future rotavator machines and how tractor rotavator systems evolve.

Conclusion

A rotavator machine, especially when paired as a tractor rotavator, offers modern farmers a powerful tool to boost efficiency, improve soil preparation, and reduce labour. But like any technology, it's not a silver bullet there are real constraints in soil type, maintenance needs, and correct operation. For Indian farmers, Mahindra Farm Machinery’s rotavator range offers a compelling combination of thoughtfully engineered features, credible support, and product diversity.

If you're considering adopting or upgrading your rotavator setup, it’s worth exploring Mahindra’s portfolio and aligning your choice with your land, tractor, and long-term maintenance ecosystem.

Sales

Service

Email