Quick Support

Sales

- +91 8888200022 / +91 7744911119

Service

- +91 8888044448

Email

- [email protected]

In the vast and varied world of modern agriculture, few inventions have made as significant an impact as the combine harvester. These powerful agriculture machinery are central to modern farming, revolutionising how we harvest crops and, ultimately, how we feed the world. In this blog, we will explore the intricate process of how combine harvesters work, their purpose, and the manifold benefits they bring to farming.

What is a Combine Harvester?

A combine harvester, commonly known as a "combine," integrates three fundamental agricultural operations—reaping, threshing, and winnowing—into one seamless process. It’s designed to efficiently harvest a variety of grain crops such as wheat, corn, soybeans, barley, and oats. This marvel of engineering allows farmers to optimise their yields and manage their lands more effectively.

How Combine Harvesters Work: A Detailed Look

Understanding the functionality of combine harvesters helps appreciate their efficiency and effectiveness. Here’s a step-by-step breakdown:

Cutting: The process begins at the front of the combine where a specially designed header cuts the crop. These headers can be adjusted for different types of crops and conditions, ensuring flexibility across various farming needs.

Feeding the Reaper: After cutting, the plants are conveyed into the combine. This is done using a series of belts or augers, which transport the crops to the threshing unit while keeping the flow steady and controlled.

Threshing: At the heart of the combine is the threshing unit. This component rapidly rotates, beating the crops to break them down and separate the grain from the stalks and other residue. It's a critical step where precision matters, as improper threshing can damage the grain or reduce its quality.

Winnowing: The threshed material moves to the winnowing area where a powerful blast of air separates the lighter chaff and debris from the heavier grains. This stage is vital for ensuring the purity and cleanliness of the harvested grain.

Collection: The cleaned grain falls through sieves into a storage tank within the combine. Meanwhile, the unwanted material is expelled out the back, often spread back onto the field as mulch or collected for other uses like animal bedding.

Unloading: Once the storage tank is full, the grain is offloaded through an auger into a transport vehicle like a truck or grain cart, ready to be taken to a storage facility or directly to market.

This process showcases the combine’s ability to handle vast amounts of crop efficiently, drastically reducing the time and labour needed compared to traditional methods.

The Purpose of Combine Harvesters

Combine harvesters or track harvesters are not just about mechanisation for convenience; they serve a critical purpose in the agricultural ecosystem:

Efficiency: Combines drastically increase the efficiency of the harvesting process, saving time and resources by handling multiple operations in one pass over the field.

Cost-effectiveness: They reduce the manpower needed for harvesting, which can significantly lower labour costs.

Improved crop handling: By automating the harvesting process, combines minimise the physical damage to crops, improving overall quality and market value.

Benefits of Using Combine Harvesters

The adoption of combine harvesters brings several benefits that go beyond just simplifying the harvesting process:

Enhanced Productivity: By speeding up the harvest process, combines allow farmers to manage larger areas more effectively, increasing overall agricultural productivity.

Reduced Waste: Advanced threshing and winnowing techniques ensure maximum grain retrieval, reducing waste and increasing the yield from each acre.

Lower Environmental Impact: Efficient fuel use and reduced field passes help minimise the carbon footprint of farming operations.

Adaptability: Modern combines are equipped with interchangeable parts that can be swapped out depending on the crop, terrain, or specific harvesting requirements, making them versatile tools in a farmer’s arsenal.

Modern Innovations

Technological advancements continue to refine combine harvester designs. Today’s machines incorporate sophisticated technologies like GPS navigation, automated steering, yield monitoring, and data analytics to further enhance efficiency and productivity. These tools enable precision agriculture, where farmers can use data to make informed decisions about planting, maintaining, and harvesting crops, optimising every aspect of farm management.

Conclusion

Combine harvesters are pivotal in modern agriculture, supporting efficient, sustainable, and profitable farming practices. They embody the spirit of innovation in agriculture, continually evolving to meet the changing needs of farmers and the demands of a growing global population. As we look towards the future, the role of combine harvesters remains crucial in ensuring food security and advancing agricultural practices worldwide.

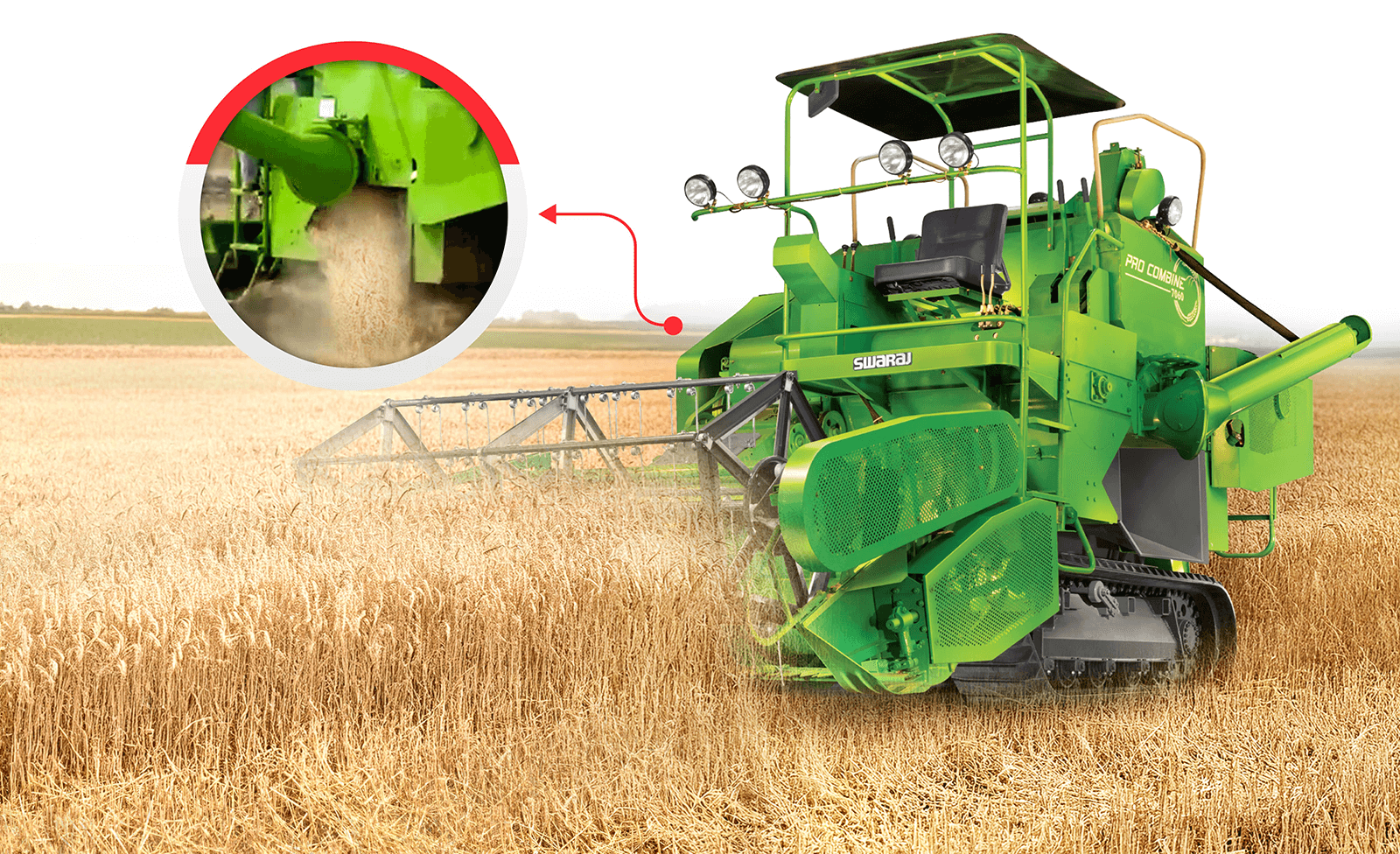

After understanding everything about Combine Harvester, the next important step is to choose the right one. Mahindra comes with a powerful combine farm machinery and one of them is a harvester called Swaraj Pro Combine 7060 Harvester. The Swaraj Pro Combine 7060 Harvester is designed to make harvesting rice easy. This machine can cut, separate, and clean the rice grains without losing many or breaking them. It helps you get a lot of rice and keeps it in good quality. You can work efficiently with this harvester, get more rice, and cover a large area of land.

By understanding the significance of these machines, we gain insights into how vital they are to our ability to sustainably manage our agricultural resources and ensure a stable food supply. This marvel of agricultural technology not only supports the livelihood of farmers but also plays a critical role in feeding the world, making it a key player in global food sustainability.