Quick Support

Sales

- +91 8888200022 / +91 7744911119

Service

- +91 8888044448

Email

- [email protected]

Ever wondered how much time and grain you lose waiting on manual harvest or mismatched machines? In India, nearly 25% of crop yields are lost each season due to delayed or inefficient harvesting. As a farm owner, choosing the right wheel harvester can transform your whole operation, saving days, money, and quality. In this guide, we'll help you match your farm size and terrain with the ideal machine: whether it's a crawler‑type or tractor‑mounted harvester. You’ll also learn how Mahindra farm machinery and mahindra farm equipment options like the Swaraj Pro Combine or HarvestMaster H12 help farmers get the maximum mileage per acre. Ready to pick smarter? Let’s begin.

Farm size is the first decision point. Small farms (1–5 acres), often in wet regions growing paddy, benefit from Mahindra’s track‑harvester models. Medium (5–20 acres) or larger dryland farms with wheat, barley or pulses may opt for wheel harvester versions of mahindra agricultural machinery. For very small holdings or tractor‑attached needs, Mahindra and Mahindra farm equipment such as the HarvestMaster H12 provides flexibility and economy. Match your crop and acreage before shortlisting.

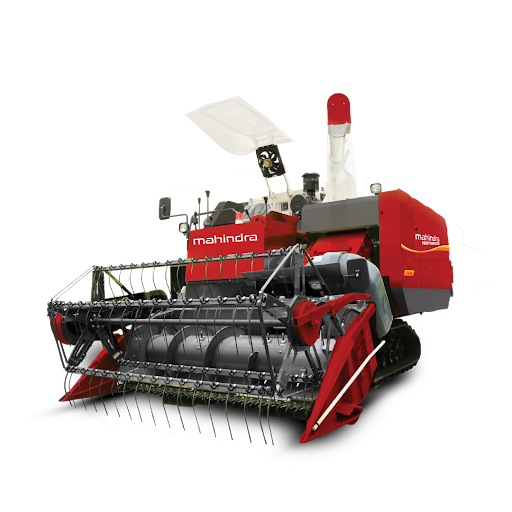

Wheel harvester models like the Swaraj 8200 Wheel Harvester are perfect for flat, dry conditions, and they offer high acreage per hour and low soil compaction. In contrast, tracked combine harvesters excel in muddy or uneven terrain because they spread weight better and reduce field damage.

Tractor‑mounted options like the Mahindra HarvestMaster are ideal for multiple crops and smaller fields, offering a low cost of operations while using your existing tractor.

Power matters. The Swaraj Pro Combine 7060 Harvester includes a 72 HP engine (Mahindra 805DI) and delivers excellent fuel efficiency and consistent throughput. Meanwhile, the Mahindra Paddy Harvester 2100 (102 HP) features a ~4.2 m cutter bar and 2500 L grain tank, reducing unloading stops and improving efficiency in dense, lodged crops. These strengths make Mahindra agricultural machinery and mahindra farm machinery ideal for balanced power-with-efficiency control.

Selecting a harvester is only half the job; after-sales support is equally critical. Mahindra and Mahindra farm equipment benefits from one of the largest dealer networks in India, offering prompt doorstep service, spare parts, warranty support and user-friendly service hotlines. This ensures minimal downtime during peak harvesting season.

While initial investment may seem high, the return often occurs within 1–2 seasons due to reduced labour costs, greater acreage covered per day, and significantly lower grain loss. For example, track harvesters reduce soil compaction and crop loss, leading to 10–15% higher yield retention in wet paddy operations. Mahindra farm machinery ensures better payback with durable engines and low maintenance needs.

Choosing the right harvester isn’t just about machinery—it’s about protecting your harvest, time, and profits. By aligning your farm size, terrain, and crop type with the right Mahindra farm machinery, you can cut losses and maximize returns. From wheel to track to tractor-mounted models, Mahindra offers solutions for every farmer’s needs. With powerful engines, fuel efficiency, and India’s widest after-sales network, you get performance backed by reliability. In the end, the right choice ensures faster harvesting, better yield retention, and a quicker return on investment.