The helix spiral blade configuration rotor can accommodate 2 types of blades, C-shaped and L-shaped, designed for ultimate soil finishing and working crop residue into the ground. Blades are arranged helically around the rotor, resulting in the blades entering the soil progressively and thus reducing power draw. Also helps achieve finer tilth of soil. Specially designed for high performance in light and medium soils in both dry and wet soil conditions such as puddling.

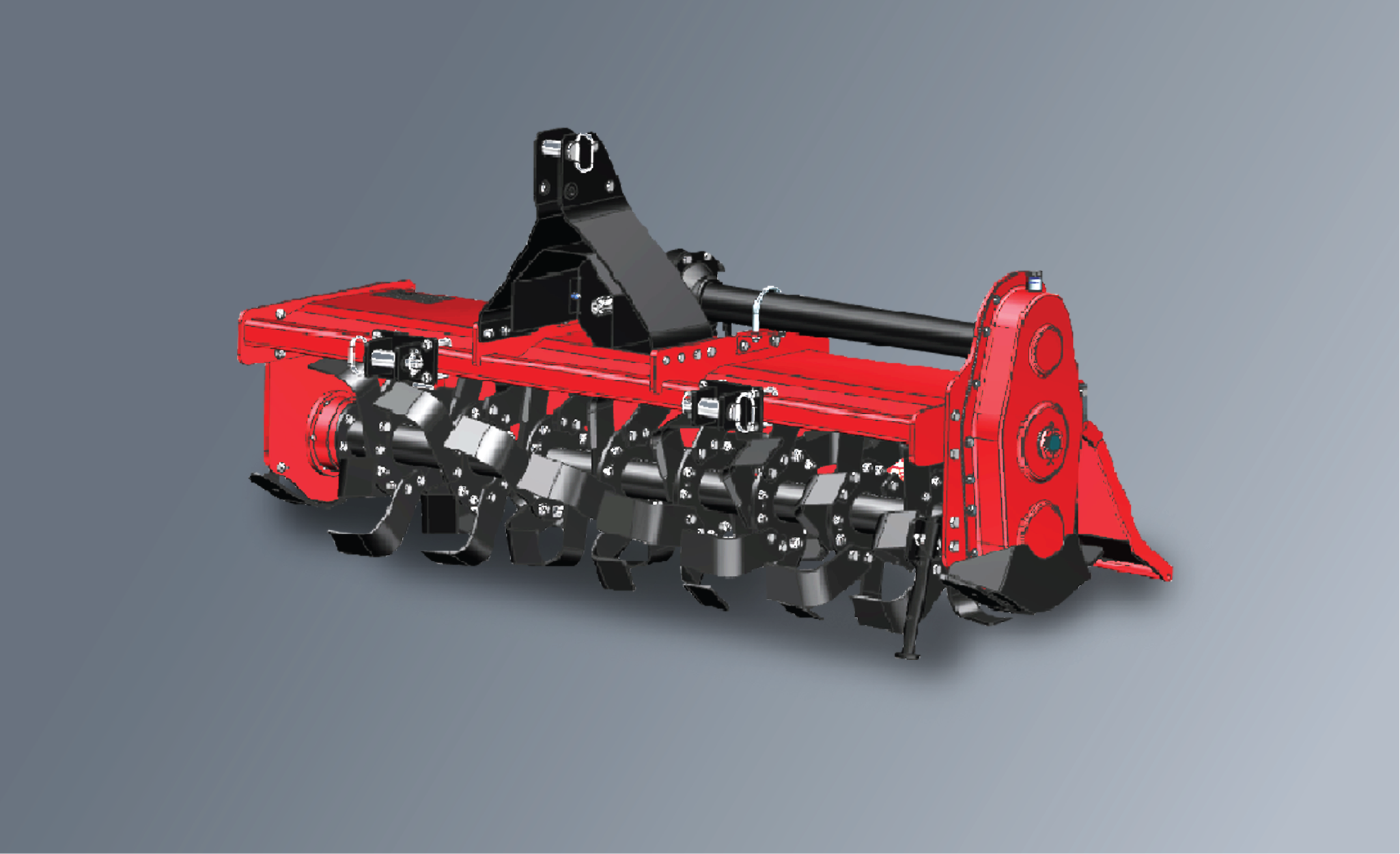

Mahindra Medium Duty UM Rotavator

The Mahindra Medium Duty UM Rotavator, a part of our lightweight series Rotary Tiller range, is meticulously engineered to deliver high-performance results in medium soils, regardless of dry or wet conditions. Its lightweight yet robust design offers a comprehensive solution, perfectly meeting the tilling requirements of forward-thinking farmers, making it an indispensable tool for modern agricultural practices.

| Parameters | Medium Duty 5' | Medium Duty 6' |

|---|---|---|

| Gearbox Type (SS / MS) | SS | SS |

| Gearbox Bevel Pair (Pinion / Module) | 13 / 6.25 | 13 / 6.25 |

| Gearbox Bevel Pair (Crown / Module) | 25 / 6.25 | 25 / 6.25 |

| Side Gear Train (Top Gear / Module) | 23//6 | 23//6 |

| Side Gear Train (Idler Gear / Module) | 35 / 6 | 35 / 6 |

| Side Gear Train (Bottom Gear / Module) | 27 & 6 | 27 & 6 |

| Centre Distance (Total) - (mm) | 366 (Str. Config.) | 366 (Str. Config.) |

| Distance (Tran. Housing axis to frame sheet) | 100.5 | 100.5 |

| Drive end side bearing configuration | Bearing 6309 | Bearing 6309 |

| Dead end side bearing configuration | Bearing 6209 | Bearing 6209 |

| Idler bearing configuration | Bearing 32008 | Bearing 32008 |

| Idler pin support type (Simply supported / Cantilever ) | Simply supported | Simply supported |

| Drive end side plate thickness (mm) | 8 | 8 |

| Dead end side plate thickness (mm) | 8 | 8 |

| Main frame sheet thickness (mm) | 4 | 4 |

| Main Frame Front Pipe | 49.5*49.5*4.5 | 49.5*49.5*4.5 |

| Frame Stacking Plates thickness (mm) | 8 | 8 |

| Trailing board sheet thickness (mm) | 2 | 2 |

| Blade type construction (C Type / L Type) | C & L Type Both (Available) | C & L Type Both (Available) |

| Rotor shaft configuration(Outward orientation / Inward orientation) | Outwards Orientation | Outwards Orientation |

| Rotor swing Diameter (mm) | Ø452 (L Type) | Ø452 (L Type) |

| Rotor swing Diameter (mm) | Ø462 (C Type) | Ø462 (C Type) |

| Rotor tube configuration | Ø76.2 X Ø65 | Ø76.2 X Ø65 |

| Rotor shaft speed (rpm) | 239 | 239 |

| Overall Dimensions (mm) | 1810*950*795 | 2000*950*795 |

| Tilling width (mm) | 1640 | 1830 |

| Recommended Tractor hp / kW range | N/A | N/A |

| Number of flanges on rotor shaft | 8 | 9 |

| Rotor Flange Diameter | Ø208 | Ø208 |

| Rotor Flange Thickness | 10 | 10 |

| Number of blades on rotor shaft | 48 | 54 |

| Number of blades per flange | 6 Blades | 6 Blades |

| Blade Overlapping (mm) | 16 | 16 |

| PTO input speed | 540 | 540 |

| Transmission type | Gear | Gear |

| Gap b/w frame sheet and rotor hull | 35 (L Type) | 35 (L Type) |

| Gap b/w frame sheet and rotor hull | 30 (C Type) | 30 (C Type) |

| Interchangeability of L & C Blade on same rotor | Yes | Yes |

| Frame construction type | Anti-clogging Type | Anti-clogging Type |

| Trailing board construction type | Z Type | Z Type |

| Three point linkage type | CAT I & QUICK HITCH | CAT I & QUICK HITCH |

| Weight (kg) | 290 (Approx.) | 315 (Approx.) |

| Sealing Type (Stub axle arrangements) Multilip seal / Duo cone mechanical face seal | Duo-Cone Seal | Duo-Cone Seal |

| Hitch Plate Thickness (mm) | 6 | 6 |

| Maximum Depth (cm) | 18 | 18 |

Get your product at the nearest Dealer

Dealer

Dealer

Sales

Sales