Quick Support

Sales

- +91 8888200022 / +91 7744911119

Service

- +91 8888044448

Email

- [email protected]

Have you ever climbed onto your tractor in the early morning, prepped your field, only to find that your cultivator isn’t doing its job cleanly? Maybe the tynes are dull, the spacing is off, or the blades are worn. That slipping feeling of less effective soil preparation, more draft resistance on your tractor, is all too familiar. In Indian farms, where every hour in the field matters, maintaining your cultivator properly means the difference between a smooth sowing bed and wasted time. In this post, we’ll walk you through essential tips for maintaining the blades and tynes of your cultivator machine, whether you’re running a standard model or a heavy-duty cultivator tractor setup. You’ll find a step-by-step approach, actionable insights, and how choosing a trusted implement brand like Mahindra Farm Machinery can reduce your hassle.

Here’s a concrete fact: tools and implements that aren’t maintained can increase fuel consumption by 5-10% because your tractor has to work harder. While specific numbers for cultivators are harder to pin down, the principle holds: if your tractor cultivator is worn or misaligned, you end up doing more work for the same result. A cultivator in the “cultivator agriculture” chain is responsible for loosening, aerating soil, and controlling weeds ahead of crops. If the tynes and blades are blunt or bent, you lose uniformity and efficiency.

Using a high-quality model, such as the ones from Mahindra, helps reduce the starting burden. Their builds include robust frames and precision-designed tynes, making your life easier from day one. Ultimately, good maintenance lengthens life, lowers running cost, and improves your return on investment in the cultivator.

Inspect blades & tynes: Before you head out, walk around your implement and check each shovel and tyne. Are the edges sharp? Are any tynes bent or missing? If you use a Mahindra cultivator, many models, such as the Rigid Tyne Cultivator, are designed for tough soil and reversible shovels. Blunt tynes mean poor weed control, higher draft, and uneven seedbeds.

Check frame, linkages & fasteners: Ensure all bolts are tight, the 3-point hitch is correctly aligned, and there are no cracks or excessive wear on the frame. Mahindra’s specification lists show strong frames (for example, spring-loaded cultivator heavy-duty) built for high HP tractors. A solid start avoids mid-season breakdowns.

Set working depth and spacing: For effective tillage, your depth and spacing between tynes must match soil type and crop. If you’re running your tractor with a cultivator agriculture implement in heavier clay, perhaps reduce depth to avoid overloading. Many Mahindra models come with adjustable settings to suit your farm.

Confirm tractor-implement compatibility: A cultivator tractor setup must match the implement’s HP rating and linkage type. For example, some Mahindra cultivators support 35-60 HP range according to model. Mismatching can cause poor performance and damage both tractor and implement.

Test run on a small patch: Before full field operation, run at working depth for a short distance to identify unusual noises, vibration or uneven performance. This quick test saves big headaches during the season.

Frequent inspections: Every few hours of work, check in on your implement. Have the tynes become clogged with roots or residue? If so, cleaning improves performance and reduces wear.

Monitor draft and tractor load: If your tractor is pulling harder than usual, it might mean the tynes are worn or the soil conditions have changed and the spacing/depth need adjustment.

Clean at the end of day: While major cleaning is for post-season, a quick rinse off heavy mud or crop residue helps prevent rust or damage. A cultivator machine that’s consistently exposed to wet soil and left uncleaned will wear faster.

Adjust for soil conditions: With changing seasons (wet to dry, heavy to lighter soils), the ideal depth, speed and spacing may change. The flexibility of the Mahindra cultivator range means you’re set up to adjust rather than being locked in.

Once the tillage window closes, now is the time to prepare your implement for rest and for next season.

Thorough cleaning: Remove all soil, mud clods and weed roots. Moist residue trapped on blades or tyne surfaces leads to rust, which eats away metal.

Sharpening or replacement of blades/tynes: If your tynes are visibly worn, bent or their edges dull, arrange for sharpening or replacement now. A fresh set of shovels means you’re ready when fields open up again.

Lubricate and protect metal: Apply rust-inhibitor or oil to bare metal surfaces after cleaning. Store your implement in a dry, covered space or clean shed to prevent rust.

Check mounting points and safety gear: The 3-point hitch, fasteners, linkage pins and safety guards should be inspected for wear. This is part of full maintenance of a cultivator machine.

Schedule service and parts ahead: With your “cultivator agriculture” mindset, know that off-season is a good time to order spare tynes/shovels, check service schedule, and book your local Mahindra implement dealer. Being proactive means you hit the field on time next season.

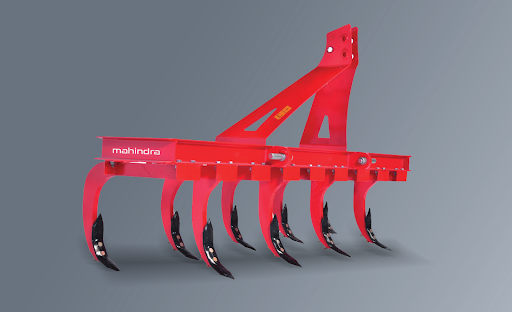

When you choose a trusted brand like Mahindra for your cultivator, you’re investing in reliability and after-sales support. Their Spring Loaded Cultivator (Heavy Duty), for instance, is available in 7 or 11-tyne models and suited to 35-40 HP and 55-60 HP tractors respectively.

Their Rigid Tyne Cultivator is engineered for tough soil and comes with durable reversible shovels.

Key benefits include strong frames, powder-coated protection, adjustable tynes, and compatibility with a range of tractors. By selecting such equipment, your maintenance efforts are supported by built-in design features. That means fewer breakdowns, lower long-term cost, and better uptime on your farm.

Ignoring mounting bolts or hitch alignment: A mis-aligned hitch means uneven tillage and creates undue stress on tynes and blades.

Using incorrect depth or pushing beyond the HP rating: Your tractor cultivator pair must match specification. Too deep or too broad a cut may work but will shorten component life.

Neglecting off-season storage: Many implement failures occur because rust sets in or bearings fail during idle months.

Assuming “set and forget”: Just because you have a premium implement doesn’t mean maintenance is unnecessary. Even Mahindra models need this checklist care.

Proper maintenance of your cultivator from active season work through off-season rest plays a crucial role in achieving efficient soil preparation, lowering fuel/tractor load, and maximising implement life. Whether you're using a standard cultivator or a fully featured tractor cultivator set-up, investing a little time in inspection, cleaning, sharpening, and storage will pay dividends. Choose a reliable brand like Mahindra Farm Machinery and stick to the maintenance habits laid out here, and your farm machinery will be ready when the next sowing window opens. It’s never too early to start: grab your checklist, walk your implement this afternoon, and give your cultivator the care it deserves.